Why Product Inspection Matters in Selecting Reliable Global Inspection Companies

Global trade has opened more doors than ever before. A business can manufacture in Vietnam, package in Mexico, and sell in the United States without ever stepping foot inside a factory. That level of opportunity is exciting, but it also creates a new level of responsibility. Buyers must trust that the products they order are made correctly, meet safety regulations, and match customer expectations. Unfortunately, that trust cannot be based on promises alone. It needs proof, verification, and quality oversight.

That is where inspection and quality assurance enter the picture. Whether you are sourcing electronics, apparel, medical supplies, automotive parts, cosmetics, or industrial machinery, you need more than good intentions from suppliers. You need transparency, accountability, and documentation. You need confidence that what you ordered is exactly what will be delivered.

And the best way to get that confidence is through third-party inspections. But not just any inspection provider will do. Choosing the right partner is just as important as selecting the right supplier. The wrong company can overlook defects, offer unreliable reporting, or lack the technical expertise your product requires. The right one can protect your business from recalls, customer complaints, and profit loss.

So how do you choose wisely? It starts with understanding the role of inspections and why they truly matter.

The Real Cost of Poor Quality

Most companies do not realize how much a single defective shipment can cost until it happens. For example:

-

A shipment of clothing arrives with incorrect sizes, forcing the retailer to discount or scrap inventory.

-

A batch of electronic chargers fails performance tests, leading to safety hazards and returns.

-

A shipment of home decor products arrives damaged because packaging wasnt tested beforehand.

-

A medical supply distributor receives expired, mislabeled, or contaminated products.

In each situation, the financial impact goes far beyond replacing products. Businesses may face negative reviews, lost customers, shipping fees, warehouse storage costs, legal penalties, and damaged brand reputation. These consequences often outweigh the cost of preventive inspection.

That is why inspection should never be seen as an optional expense. It is an investment in brand protection, customer trust, and long-term stability.

Why Product Inspection Is the Foundation of Quality Assurance

Before selecting an inspection partner, it is important to understand what inspection really includes. Proper inspection evaluates product appearance, measurements, labeling, functionality, performance, packaging, safety compliance, and consistency. It ensures that products are manufactured according to approved samples, industry standards, and purchase agreements.

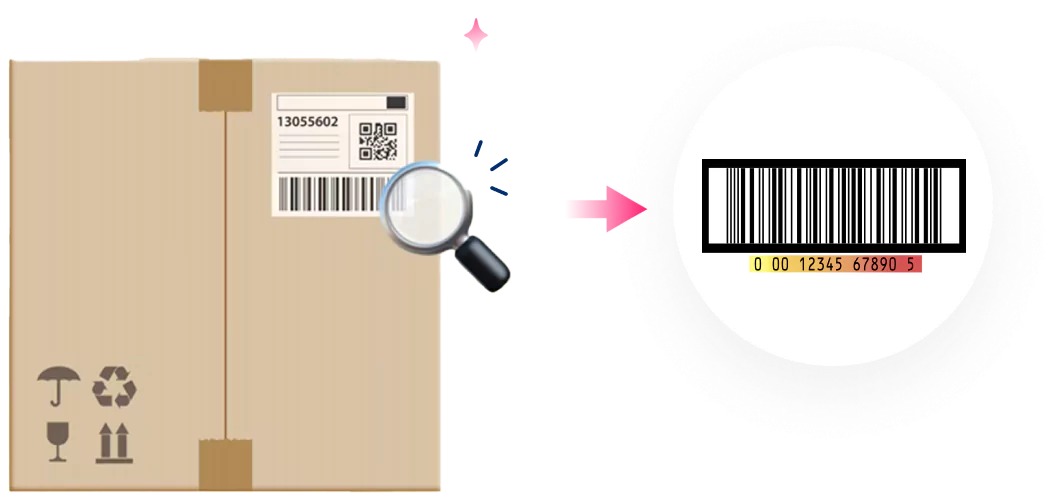

A professional inspector acts as your eyes inside the factory. They check details that a buyer may never think about, such as stitching alignment, electrical grounding, chemical safety compliance, torque resistance, barcode accuracy, weight tolerance, and packaging durability. These details determine whether a customer receives a flawless product or a disappointing one.

Todays marketplace is competitive, and customers are not shy about sharing bad experiences online. One defective shipment can hurt a brands credibility instantly. That is why Product Inspection has become a necessary step rather than an optional quality add-on.

The Difference Between a Good Inspector and a Great One

Many companies assume all inspection services provide the same value, but that is not true. Some only perform surface-level checks, while others follow strict protocols. Some specialize in certain industries, while others lack technical expertise. Some send detailed reports with photos and measurements, while others offer vague summaries that leave clients unsure.

A great inspection provider brings industry-specific knowledge, modern tools, strong ethics, clear communication, and repeatable procedures. They not only identify problems, but help prevent them in future production runs. Their goal is improvement, not just observation.

When choosing a third-party inspector, ask yourself:

-

Do they understand my product category?

-

Do they know compliance rules for my selling region?

-

Are their reports easy to understand and actionable?

-

Do they offer scalable support as my business grows?

-

Do their inspectors receive ongoing training?

-

Are their audits fair, unbiased, and transparent?

If the answer is no, it may not be the right fit.

Why Choosing the Right Inspection Partner Matters

Selecting an inspection provider is a strategic decision. Your partner should operate with the same commitment to quality as your internal team. They should care about safety, reliability, and customer satisfaction as much as you do.

The right partner protects you from:

-

Shipment delays

-

Supplier dishonesty or corner-cutting

-

Manufacturing inconsistencies

-

Product recalls

-

Warranty claims

-

Regulatory violations

-

Consumer dissatisfaction

They help establish trust between suppliers and buyers, especially when dealing with international production. Clear expectations lead to fewer disputes and smoother operations.

When to Schedule Inspections

Timing plays a huge role in effective quality management. Inspection should not happen only at the end of production. The most successful brands schedule inspections throughout the manufacturing process:

-

Before Production

Confirms raw materials and factory readiness.

-

During Production

Detects issues early, preventing mass defects.

-

Before Shipment

Final verification before products leave the facility.

-

Upon Arrival

Ensures nothing was damaged in transit.

Consistent inspection reduces surprises and promotes continuous improvement.

Common Mistakes Companies Make

Even experienced buyers sometimes make avoidable mistakes, such as:

-

Relying solely on supplier self-reporting

-

Choosing an inspection partner based only on price

-

Assuming compliance standards are the same worldwide

-

Skipping inspection to speed up delivery

-

Ignoring packaging testing

-

Selecting a provider without verified credentials

Each oversight increases business risk.

Quality assurance requires skill, attention to detail, and strong communication. Cutting corners may offer short-term savings, but long-term consequences can be far more expensive.

What to Expect From a Reliable Inspection Provider

A credible inspection provider should deliver:

-

Clear pricing and transparent processes

-

Detailed reports with photos, measurements, and findings

-

Experienced inspectors trained in relevant industries

-

Ethical standards and confidentiality agreements

-

Consistent inspection methodologies

-

Honest explanations of potential risks

-

Customer support that prioritizes your concerns

Professionalism matters. You are not just buying a service. You are trusting someone with your brands reputation.

The Bottom Line

Global sourcing will continue to grow, and so will competition. Businesses that prioritize quality today will become the brands consumers trust tomorrow. Whether you manufacture overseas, partner with multiple suppliers, or operate in a highly regulated industry, inspection is a crucial safeguard.

Working with experienced inspection companies gives you more than basic reporting. It provides insight, confidence, and long-term protection. It helps ensure that every shipment reflects your standards, values, and customer expectations.