Supply Chain News: The New Standards for Supply Chain Visibility in 2025

The latest supply chain news shows a decisive shift: visibility is no longer defined by shipment milestones—it now reflects end-to-end transparency across suppliers, inventory, logistics, and risk signals.

Supply chain visibility has moved from a technical aspiration to a core operating requirement as disruptions, regulatory pressure, and customer expectations intensify. In 2025, companies are rebuilding visibility frameworks around real-time data, event-level tracking, and predictive intelligence. The latest supply chain news shows a decisive shift: visibility is no longer defined by shipment milestonesit now reflects end-to-end transparency across suppliers, inventory, logistics, and risk signals. With global networks growing more complex, the new standards for visibility are reshaping how organizations plan, operate, and respond.

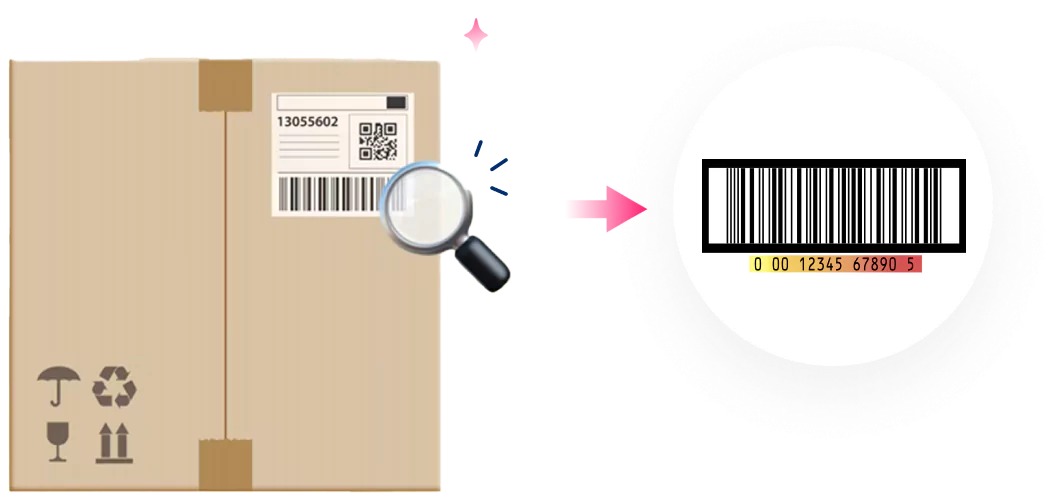

Real-Time, Event-Level Tracking Becomes the New Baseline

For years, visibility meant periodic updates from carriers or warehouse systems.In 2025, real-time, event-level tracking is rapidly becoming the industry standard.

Recent supply chain news highlights a surge in adoption of:

-

GPS-enabled sensors on containers, pallets, and high-value cargo

-

IoT devices monitoring temperature, shock, and humidity

-

Automated status feeds from carriers and 3PLs via API connections

-

Exception alerts for routing deviations, port congestion, or dwell-time spikes

Shippers want to know not only where their goods are, but what condition they are inand whether a disruption is forming ahead of them.

Inventory Visibility Extends Beyond the Four Walls

A major shift in 2025: inventory visibility now spans stores, suppliers, DCs, in-transit nodes, nearshore plants, and even repair and return centers.

The latest supply chain news shows companies focusing on:

-

SKU-level visibility across the entire network

-

Store-level stock accuracy supported by RFID and computer vision

-

In-transit inventory tracking that integrates with replenishment systems

-

Cross-channel allocation logic that responds in real time

Retailers and manufacturers are no longer satisfied with periodic inventory snapshots. They need dynamic visibility that aligns with omnichannel demand and shorter planning cycles.

Digital Twins Enable Predictive Visibility Instead of Reactive Updates

Digital twinsvirtual replicas of supply chainsare becoming central to visibility improvements.Rather than reporting what has happened, digital twins help predict what will happen.

According to recent supply chain news, companies are using digital twins for:

-

Simulating port delays and recalculating ETA windows

-

Forecasting network congestion across warehouses and cross-docks

-

Predicting stockouts based on demand signals and supplier performance

-

Testing alternative transportation routes under various conditions

Predictive visibility allows operators to pre-empt problems rather than react to them, reducing service failures and firefighting.

Supplier Transparency Expands Beyond Tier 1

Supplier visibility has historically been limited to Tier 1 partners.In 2025, regulatory shifts, ESG mandates, and risk events are forcing companies to map deeper into multi-tier networks.

Recent supply chain news shows growing adoption of:

-

Tier 2 and Tier 3 supplier mapping tools

-

AI-driven risk scoring based on financial, geopolitical, and ESG factors

-

Continuous monitoring of supplier disruptions

-

Material and component traceability for compliance

This deeper transparency is becoming essential in industries like automotive, electronics, apparel, and food.

Port, Carrier, and Customs Visibility Become Integrated

Fragmented transportation data has long been a bottleneck.In 2025, companies are consolidating visibility across:

-

Vessel schedules and port congestion forecasts

-

Rail and intermodal dwell-time analytics

-

Carrier performance benchmarks

-

Customs clearance statuses

This integrated view allows logistics teams to adjust routing, rebalance inventory, and communicate proactively with commercial teams.

The latest supply chain news shows growing emphasis on multi-modal visibility platforms that combine ocean, air, truckload, intermodal, and parcel data into a single interface.

Predictive ETAs Replace Static Milestone-Based Tracking

Accurate delivery windows are becoming non-negotiable.Predictive ETAspowered by machine learningnow outperform traditional milestone-based tracking.

Key capabilities trending in supply chain news:

-

AI models that incorporate weather, port congestion, and chassis availability

-

Dynamic re-forecasting as conditions change

-

Lane-level ETA accuracy targets used in carrier scorecards

-

Proactive notification systems that alert customers before delays materialize

This shift toward predictive visibility is improving planning, reducing demurrage, and stabilizing last-mile fulfillment.

Risk Visibility Integrates Geopolitics, Cyber Threats, and Cost Volatility

Visibility now includes more than supply and transportation.Companies are building dashboards that integrate risk signals from across the world.

The latest supply chain news highlights rising adoption of:

-

Geopolitical risk monitoring tied to sourcing and logistics routes

-

Tariff and trade policy tracking impacting landed costs

-

Cybersecurity threat alerts affecting suppliers and logistics providers

-

Financial health signals from critical vendors

Executives want visibility of exposure, not just visibility of movement.

Data Quality and Interoperability Become Board-Level Issues

Visibility upgrades fail when data is inconsistent, delayed, or siloed.In 2025, companies are prioritizing strong data governance and system interoperability.

Key developments in recent supply chain news:

-

Unified data models across ERP, WMS, TMS, planning, and procurement

-

API-based integrations replacing outdated EDI-only systems

-

Data validation layers to ensure quality before decision models use it

-

Shared data standards across suppliers and logistics partners

Executives increasingly view data quality as a foundational capabilitywith direct financial impact.

Strategic Takeaways for Supply Chain Leaders

As visibility standards evolve, several priorities stand out:

-

Build real-time visibility across shipments, inventory, and suppliers

-

Adopt digital twins to enable predictive planning and scenario modeling

-

Expand multi-tier supplier mapping and risk monitoring

-

Upgrade transportation visibility with predictive ETAs

-

Consolidate data into unified orchestration layers

-

Strengthen data governance to improve decision accuracy

-

Integrate risk signals into everyday operational workflows

Visibility is now both a resilience strategy and a competitive advantage.

Visibility Becomes a Strategic Operating System

The latest supply chain news confirms that visibility in 2025 is expanding from tracking and tracing to full-spectrum intelligence.Companies that rely on fragmented updates will struggle to navigate volatility. Those that build real-time, predictive, and multi-tier visibility systems will make faster decisions, reduce costs, and operate with confidence in uncertain conditions. Visibility is no longer a toolit is the operating system of modern supply chains.