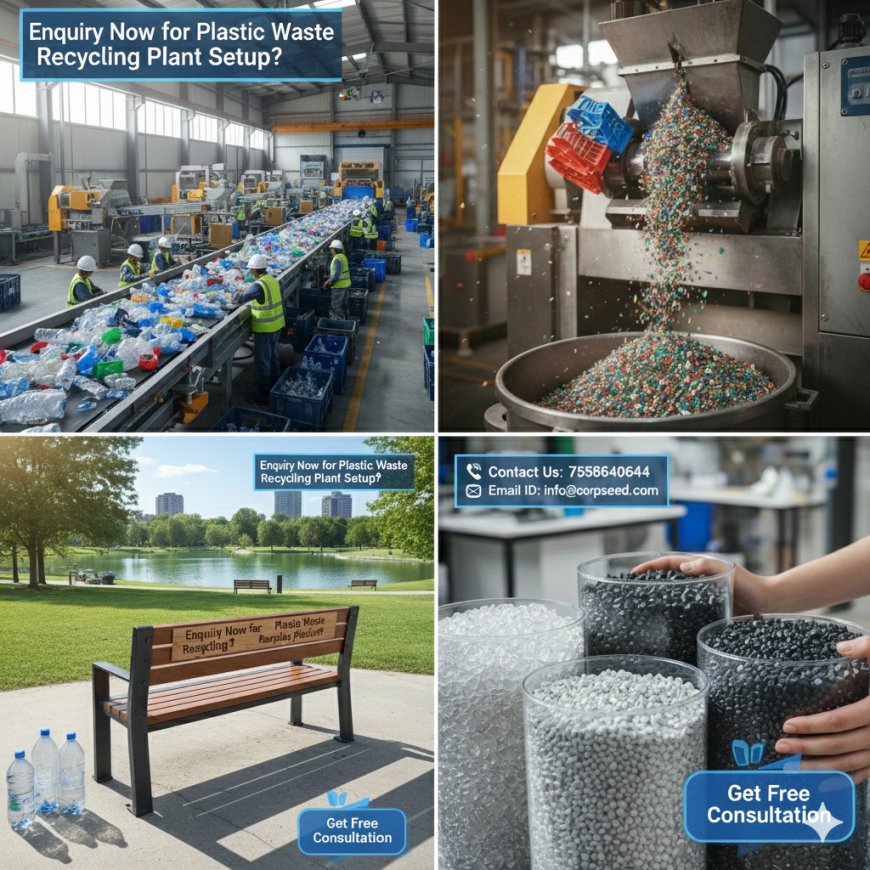

Plastic Recycling Business Guide: Setup, Cost, Machinery.

Get to know about the insights into how to set up a plastic recycling business plant, its cost, and what machines are used, along with other useful information.

Introduction

The recycling business is one of the fastest-growing sectors in India, which is powered by growing plastic consumption, government regulations, and increasing awareness about sustainability. A plastic recycling plant can be set up and can yield great profits if executed properly. The guide covers each and every aspect needed to grow a plastic waste recycling business, ranging from understanding types of plastic to setting up everything.

Understanding Plastic Types: Which Plastics Are Most Profitable to Recycle?

Starting a plastic recycling plant can be hectic, but getting to know about the plastics that give better profit is necessary.

- PET (Polyethylene Terephthalate): It is the most commonly used plastic in water bottles, soft drinks, and the packaging of food, and is also highly profitable. There is high demand from the textile and packaging industries. It is also easy to access and convert into recyclable items.

- HDPE (High-Density Polyethylene): This is used in shampoo bottles, milk cans, and grocery bags. Also has a strong market demand. The recycled HDPE granules can get a good market rating as they are consistently in demand.

- PP (Polypropylene): This type of plastic is used in the automobile industry, household items, and packaging materials. It is very lightweight and is used widely as it yields good profit margins and is used in granule production. Apart from this, it is also valuable for manufacturing.

How to Identify and Sort Plastics Correctly (Plastic Codes Explained

Sorting is crucial in plastic recycling, ensuring high purity and superior output quality.

Plastic Identification Codes

|

Code |

Type |

Common products |

Recyclability |

|

1 |

PET |

Bottles, Containers |

Highly recyclable |

|

2 |

HDPE |

Containers, Cans |

Excellent |

|

3 |

PVC |

Pipes, Sheets |

Difficult |

|

4 |

LDPE |

Carry bags, Films |

Moderate |

|

5 |

PP |

Housewares |

Good |

|

6 |

PS |

Disposable items |

Poor |

|

7 |

Others |

Mixed plastics |

Varies |

Step-by-Step Workflow of a Plastic Recycling Plant

A proper step-by-step guide is used to set up a plastic recycling plant, and it is given as follows:

- Collection: Plastic waste is sourced from houses, scrap dealers, industries, and municipalities.

- Sorting: It is done by manual picking, shredding, and a magnet separator.

- Washing and Drying: It is then washed to remove dirt, adhesive, and residues, and dried after that.

- Shredding: Material is processed into flakes for downstream use.

- Pelletizing: Flakes are then converted into granules by melting them.

- Packaging and selling: Granules are then packed and sold to manufacturers.

All these steps contribute to the plastic recycling business cycle.

Where to Source Plastic Waste for Your Plant

When running a waste recycling business and to make sure its profitable, sourcing of the material should be important, and the top sources are:

- Municipal corporations

- Scrap dealers

- Industries

- E-commerce packaging waste

- Retailers like stores and malls

Environmental Impact of Plastic Recycling (Numbers That Matter)

Operating a plastic waste recycling plant does not just yield income but also contributes to sustainability.

Major Environmental benefits are:

- Recycling 1ton of plastic saves up to 5700 kWh of energy.

- Greenhouse emanation is reduced up to 70%

- Landfill usage has also dropped.

- Reduces marine pollution

Safety Guidelines for Workers in Plastic Recycling Facilities

Safety is something that cannot be taken for granted in a recycling plant because of the sharp waste, chemicals, and other things.

Some important safety measures are:

- PPE kit

- Fire safety systems

- Regular maintenance of machines

- Dust control systems

- Training of workers on waste handling

Frequently Asked Questions (FAQ)

1. What is the cost of setting up a plastic recycling plant?

Small-scale: ?815 lakhs

Medium-scale: ?2545 lakhs

Large-scale: ?50 lakhs?1 crore+

Cost varies based on machinery, land, labour, and utilities.

2. How much profit can a plastic recycling business generate?

Profit margins range from 10% to 30%, depending on plastic type and production scale.

3. Is starting a plastic recycling plant in India profitable?

Yes. High demand for recycled granules, government support, and low raw material costs make it profitable.

4. Can I start a plastic recycling plant in Uttar Pradesh?

Yes, UP has multiple industrial clusters and government subsidies. Proper licenses (Consent to Establish, Factory License, etc.) are required.

5. What is a small-scale plastic recycling plant?

A low-capacity unit that handles 50200 kg/hr, ideal for start-ups and low-budget entrepreneurs.

Conclusion

A plastic recycling business plant in India is a profitable opportunity, but also a greater step towards sustainability. With plastic consumption on the rise, there is a greater surge for recycled granules and government support. The business offers growth in the long-term. By getting to know the plastic types, following proper methods, and making sure that the sourcing and safety practices are fair and efficient, business owners can build a plastic recycling business that is successful. Whether starting with a small or expanding it into a proper plastic waste recycling plant, success follows when there is strategic planning and proper operations.