Innovative Metal Solutions Shaping the Future of Construction

Steelmart is highly valued for its recyclability and efficient reuse, reducing environmental impact.

In todays rapidly evolving industrial landscape, metal materials play a critical role in supporting infrastructure, manufacturing, and development projects. From residential buildings to large-scale industrial facilities, the demand for reliable, durable, and versatile materials continues to grow. Metals are valued for their strength, adaptability, and long service life, making them essential for projects that require both performance and longevity. Selecting the right material ensures structural integrity, safety, and cost efficiency across various applications.

The Role of Steel Products in Construction and Manufacturing Sectors

Steel remains one of the most widely used materials due to its exceptional strength and flexibility. It supports applications ranging from frameworks and roofing to machinery and transportation components. Steel products offer consistency in quality and performance, allowing engineers and builders to meet demanding specifications. Their ability to withstand environmental stress while maintaining form makes steel a preferred choice for long-term projects that require stability and reliability.

Key Characteristics That Define High Quality Steel Materials

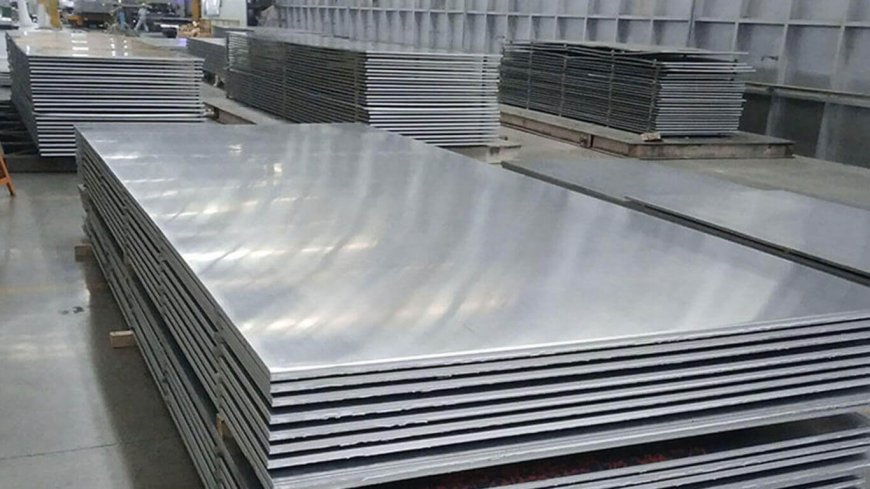

High-quality steel materials are recognized by their uniform thickness, smooth surface finish, and resistance to corrosion. These characteristics ensure ease of fabrication and consistent performance during use. Steel sheet products, in particular, are valued for their flatness and adaptability, allowing them to be cut, shaped, and welded efficiently. Manufacturers and builders rely on these qualities to achieve precision, durability, and aesthetic consistency in their projects.

Applications of Steel Sheet Across Multiple Industries

Steel sheet is widely used across industries due to its versatility and strength. In construction, it is commonly applied in roofing, wall panels, and structural components. In manufacturing, it supports the production of appliances, automotive parts, and industrial equipment. Its consistent surface and strength make it suitable for both functional and decorative purposes, enabling industries to meet performance requirements while maintaining visual appeal.

How Reliable Suppliers Support Industry Growth and Stability

Reliable suppliers play a crucial role in maintaining material availability and quality consistency. Companies such as steelmart provide access to well-processed and standardized metal products, helping businesses meet project timelines and specifications. Dependable sourcing reduces the risk of delays, material defects, and cost overruns. By working with trusted suppliers, industries benefit from steady supply chains and improved operational efficiency.

Manufacturing Processes That Enhance Steel Performance and Quality

Modern manufacturing processes have significantly improved steel performance through advanced rolling, coating, and finishing techniques. These processes enhance strength, corrosion resistance, and surface quality, making steel suitable for demanding environments. Controlled production ensures uniform dimensions and predictable behavior, which are essential for large-scale industrial and construction projects. Such advancements allow steel to remain competitive and adaptable to evolving industry needs.

Importance of Quality Control and Standards in Steel Production

Quality control is essential in ensuring steel products meet industry standards and safety requirements. Rigorous testing and inspection verify thickness accuracy, tensile strength, and surface consistency. Adhering to recognized standards ensures that materials perform reliably under stress and environmental exposure. This focus on quality provides confidence to engineers and builders, enabling them to deliver safe and durable structures.

Sustainability and Environmental Considerations in Steel Usage

Sustainability has become a key consideration in material selection. Steelmart is highly valued for its recyclability and efficient reuse, reducing environmental impact. Many steel products are manufactured using recycled content, supporting environmentally responsible practices. By choosing steel, industries contribute to resource conservation and reduced waste, aligning with modern sustainability goals while maintaining high performance.

Choosing the Right Steel Products for Specific Project Needs

Selecting the appropriate steel product requires careful consideration of project requirements, environmental conditions, and load demands. Factors such as thickness, finish, and strength rating influence performance and longevity. Consulting with experienced suppliers helps ensure the chosen material aligns with design specifications and budget constraints. Proper selection minimizes maintenance needs and enhances overall project success.

Long Term Benefits of Investing in Quality Steel Materials

Investing in quality steel materials delivers long-term value and reliability. Durable steel products reduce the need for frequent repairs or replacements, lowering lifecycle costs. Their consistent performance enhances structural safety and operational efficiency across applications. Businesses that prioritize quality materials benefit from improved project outcomes and stronger reputations within their industries.

Conclusion

Steel continues to be a cornerstone of modern development due to its strength, versatility, and sustainability. Products such as steel sheet support a wide range of applications, offering reliability and adaptability for diverse industry needs. Trusted suppliers like steelmart contribute to industry success by providing consistent quality and dependable service. By understanding material properties, sourcing responsibly, and prioritizing quality, industries can achieve efficient, durable, and sustainable project outcomes that stand the test of time.