How Realology™ Transforms Drilling Fluid Rheology Monitoring for Better Decision-Making

Drilling operations depend on accurate data and performance with safe well conditions. One of the most important factors behind smooth drilling is fluid rheology. Rheology explains the drilling fluid behavior under different temperatures. It also shows under pressures and flowing conditions. If rheology changes, the complete drilling system gets affected by it.

Drilling operations depend on accurate data and performance with safe well conditions. One of the most important factors behind smooth drilling isfluid rheology. Rheology explains the drilling fluid behavior under different temperatures. It also shows under pressures and flowing conditions. If rheology changes, the complete drilling system gets affected by it.

In present complex wells, human measurements are not enough. Engineers need fast and more real time information. That is why rheology, an advanced monitoring solution, is required. It has become one of the transforming drilling operations for todays engineers. It provides continuous insights and better control. It also supports data driven solutions for improved well performance.

Let us explore how Realology improves the drilling teams. And also understand how they manage rheology.

What is Rheology in Drilling?

Rheology controls thedrilling fluidflow in the well. It affects the hole cleaning and pressure balance. It also affects the suspension of cuttings with lubrication. Good rheology supports the stability of the well. It also impacts drilling efficiency. If viscosity or gel strength changes, the drilling rate can drop. Fluids might fail to lift the cuttings or maintain the pressure. It also impacts safety.

Poor rheology increases the chances of losses and stuck pipes. It also affects kicks and surface equipment at the start. It has become a need for accurate monitoring. Traditional tests depend on manual checks. These tests take time. These cannot show the changes happening inside the well. Realology solves the problems by giving continuous measurements. It is also helpful in providing rheology measurements.

How Realology Works in Drilling Operations?

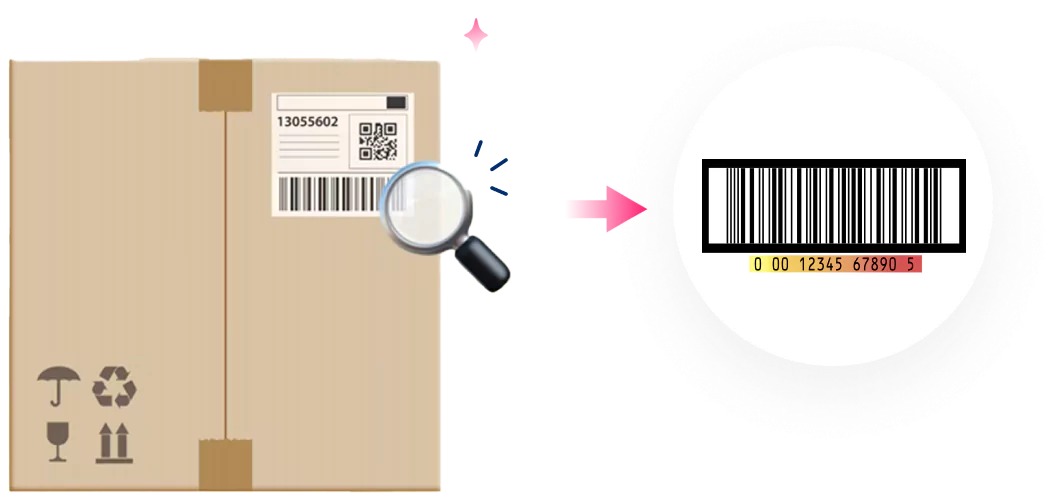

Realology uses advanced sensors. These are automated systems that are helpful in analysing fluid behavior. The results are available in real time. These also help engineers to react at the right moment.

Continuous Measurements

Rather than waiting for human lab readings, Realology provides instant data. It monitors the viscosity and gel strength. It also measures the flow patterns automatically.

Sensors and Testing

It provides smart sensing with automated testing. Sensors detect small changes in fluid behaviors. These details help the engineers to understand how the fluid is reacting inside the well.

Accurate Data

It provides correct data, which helps in faster decision making. Realology removes the guesswork. It provides stable and repeated readings. It also allows precise adjustments in fluid properties.

Easy Integration

It helps in easy integration with rig systems. The systems can connect with the rig software. It also connects with the reporting tools. This provides operators with a complete understanding of the drilling performance.

Why Real Time Rheology Important?

Wells today are deeper, hotter, and more complex. The manual rheology testing could not match the speed needed. Real time data solves problems before they grow and increase.

They provide a fast response to the fluid changes. Mud properties can shift with temperature and pressure. Realology shows these changes instantly. They support optimised drilling parameters. Engineers can easily adjust the pump rate and weight on bit. They also manage the fluid additives with confidence.

They support better communication between the teams. Clear data improves coordination. They manage coordination between the engineers, rig staff, and supervisors. It also supports reduced environmental impact. Better fluid control reduces the chemical waste and fluid disposal for the disposal volumes.

How to Choose Realology for Modern Drilling

Realology is made for companies that are looking for reliable operations. It supports safe drilling with efficient planning. It also controls the costs. For wells with high risk and complex formations, Realology becomes more valuable. With the combination of automation and intelligent analysis, Realology set a new standard for fluid rheology. It helps in making the team smarter and smarter.

Final Call

The backbone of safe and efficient drilling is fluid rheology. Realology takes rheology monitoring to the next level. They offer continuous and correct real time data. With better insights and stronger control, they reduce the drilling risks. For modern energy operations, Realology is the most powerful tool. As it transforms decision making.

FAQs

Q. Why is rheology important in drilling?

A. It affects hole cleaning and well stability. It also reduces the risks.

Q. How does Realology improve the drilling operations?

A. It improves real time rheology data. It also speeds up the adjustments.

Q. Can Realology replace human rheology tests?

A. Yes, Realology replaces human rheology tests.

Q. Are Realology suits to every well type?

A. Yes, Realology suits every well type.