How Can a Chinese Injection Mould Maker Support Your OEM Projects

Injection Mould Maker

OEM projects need parts that fit well, last long, and arrive on time. Many global brands look to China for this work because the country offers strong skills, smart tools, and stable supply chains. A China injection mould maker helps OEM teams turn ideas into solid products. Injection moulding shapes plastic into car parts, tools, and daily items with care and speed. This article explains how Chinese mould makers support OEM work through fast output, clear design, material choice, and cost care. The focus stays on knowledge that helps buyers plan projects with trust and ease.

Fast output that meets OEM demand

A China injection mould maker supports OEM projects through fast production. The injection moulding method allows teams to make many parts in short cycles. OEM brands often need large volumes to meet market needs. Chinese factories plan lines that run for long hours with stable results. This speed helps brands avoid delays and stock gaps.

Key points that support fast output

? Short moulding cycles that raise daily output

? Multi-cavity moulds that shape many parts at once

? Planned workflows that cut idle time

? Skilled teams that fix issues during runs

This approach helps OEM buyers keep schedules without stress.

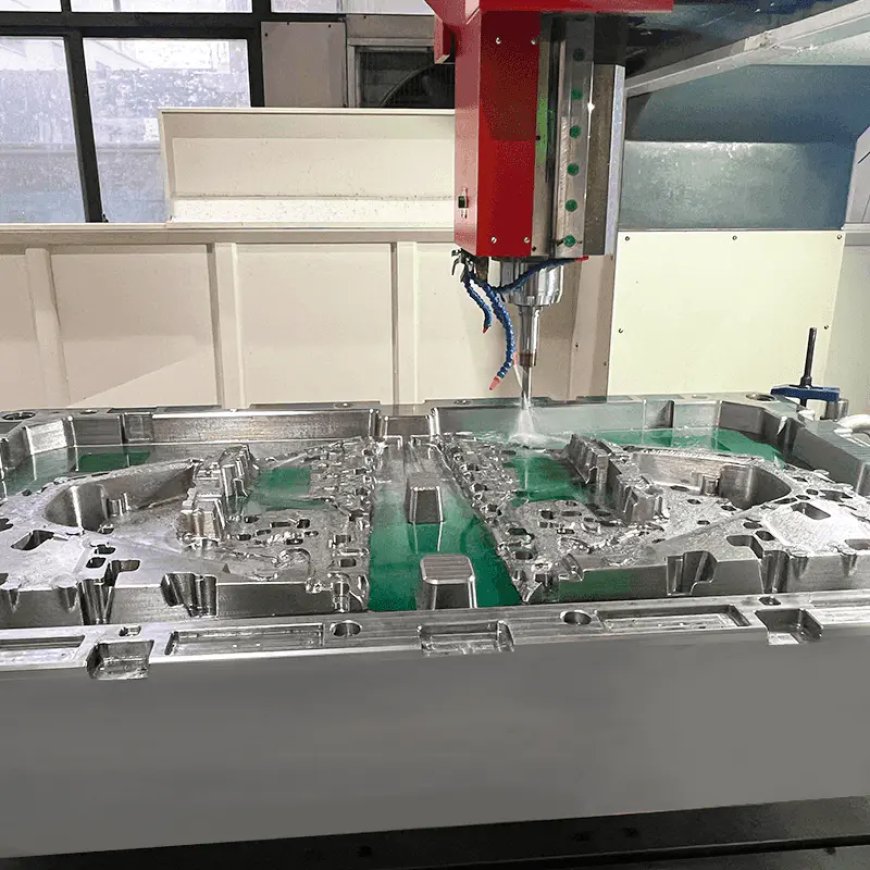

Accurate shapes and steady quality

OEM projects depend on parts that match drawings and fit systems. A China injection mould maker uses CAD and CAM tools to plan moulds with care. These tools guide cutting and shaping with clear limits. Each mould creates parts of the same size and form. This steadiness lowers waste and cuts rework. OEM teams gain trust when each batch matches the last one.

Quality gains come from

? Clear digital models before cutting steel

? Careful tool making that holds tight limits

? Routine checks during moulding runs

? Clean mould surfaces that shape sharp details

Such control helps OEM brands build safe and reliable products.

Support for complex OEM designs

Many OEM parts carry curves, ribs, clips, and fine marks. A China injection mould maker handles such shapes with skill. Injection moulding fills deep spaces and thin walls with ease. This strength allows designers to add style and function in one part. Dash panels, trims, and housings show this value. Fewer joined parts mean fewer faults.

Design support includes

? Moulds that copy fine textures

? Slides and lifters that form hidden shapes

? Clean edges that reduce handwork

? Parts that leave the mould ready for use

This freedom helps OEM teams build smart designs without heavy assembly.

Wide material choice for OEM needs

OEM products need plastics with clear traits. Some need strength. Others need lightweight or heat care. A Chinese plastic injection mold supplier offers many material options. Thermoplastics and thermosets serve different uses. This range helps OEM buyers match parts to real use cases.

Material support includes

? Plastics that resist heat and wear

? Light grades that cut product weight

? Stable resins that hold shape over time

? Recyclable options that meet green goals

With the right plastic, OEM parts perform well in daily use.

Cost care across the project life

Cost matters in OEM work. A custom injection mould manufacturer in China keeps costs under control through smart planning. Injection moulding cuts waste since moulds shape only what is needed. Skilled teams also reduce labour steps. Energy use stays balanced through modern machines.

Cost benefits include

? Less scrap from the exact mould cavities

? Fewer workers per line due to automation

? Long mould life that spreads the tool cost

? Stable output that avoids rush charges

These gains help OEM buyers protect margins without cutting quality.

Conclusion

OEM projects need partners that bring skill, scale, and trust. Chinese mould makers meet these needs through speed, quality, design care, material choice, and cost balance. They help brands turn plans into real products that serve markets well. When choosing a partner, buyers look for steady support across each stage of work. Liberal Mould is an injection mould manufacturer in China that understands these needs and supports OEM goals with strong moulding knowledge and clear project focus.