What Printing Options Work Best for Custom Cereal Boxes?

Discover different printing techniques feasible for custom cereal boxes. The guide shares color systems as well for reproducing the brand palette.

Printing options are critical in transforming plain packaging into a compelling statement. Also, quality printing rejuvenates its marketing ability. Perceived value is enhanced merely because of branding elements and product details printed on boxes. For instance, the allergens are associated with food items.. Everyones health is essential. And conveying ingredients as well as allergens contributes to the extreme care of customers.

In the end, high-quality printing satisfies users. They tend to lean more towards that brand. Why is it so? Because such brands are transparent. You can further print instructions on safeguarding food quality. Or some recipes, if applicable. Moreover, the article today is about printing techniques for custom cereal boxes. We have covered the pros and cons to aid in effective selection.

Effective Primary Printing Methods forCustom Cereal Boxes

Lets discuss two of the most important players. These types are considered the most effective for custom food packaging boxes with logos, food pictures and multiple other elements. Both put forth their advantages and limitations. One is offset printing. It is ideal for larger units. And can cover wide-ranging material types. Conversely, digital printing is a modern approach. It benefits small businesses more. And there is zero setup cost.

Offset Printing Perfect for Large-Scale Units

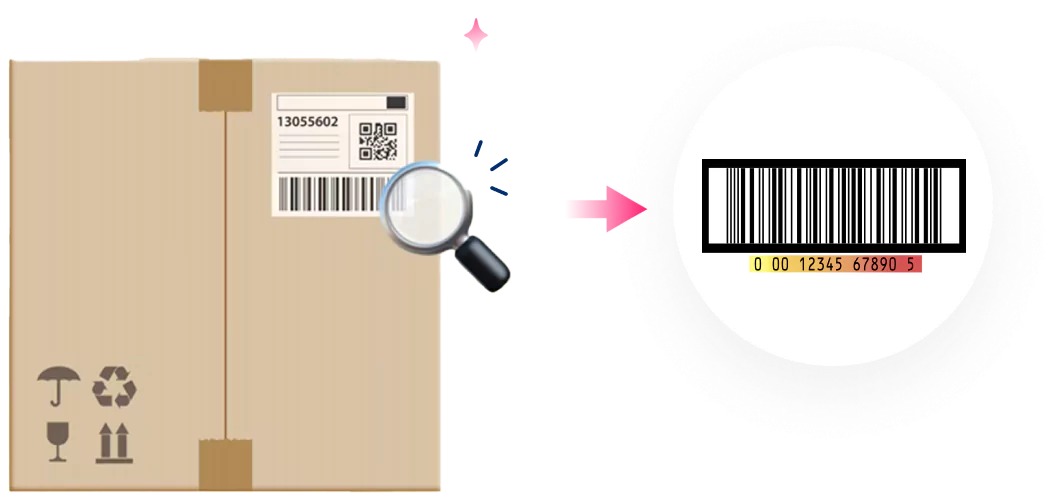

Offset printing utilizes metal plates to transfer the image indirectly on an offset cylinder. It then rolls the ink onto the cardboard substrate. The prime role of this separation here is to make sure the transfer is the crispiest. Moreover, this printing is apt for large-scale custom cereal boxes wholesale. More than five thousand units, to be precise. And the outcome is the finest-quality images.

Another advantage is the significant drop in price. So, it is among the best options for large quantities. It can even print on a vast range of material types. On the negative side, offset printing requires a high setup cost. There is a need for specialized aluminum plates for every color used. And this factor does not depend on order size.

Digital Printing Perfect for Small Brands & Orders

The second important and modernized version is digital printing. Its famous for being accessible to smaller brands. Also, it eradicates the need for specialized plates. As a result, digital printing becomes financially viable. It is even suitable for small orders, those of less than five thousand units. Another perk is the reduction in lead times. Print files are ready to run immediately.

Conversely, there are some negative factors that negate its use to some extent. First is the constant per-box cost. So, it is highly costly for large orders. Besides, the quality is not as clean as offset printing. If your cereal boxes require fine text, it is better to opt for the previous option. Achieving color accuracy is challenging too.

Color Systems for Reproducing Brand Hues

For maintaining brand consistency on the shelf, the content will share two key color systems. One is the universal method for printing. It is CMYK. Four different colors combine to form multiple shades on the paperboard. Cyan, magenta, black and yellow. This color system is highly advantageous for detailed illustrations and gradients. Also, to achieve imagery complexity on custom printed boxes with window or other intricate features, CMYK is appreciable.

To eradicate color variation, there is PMS. Pantone Matching System comprises pre-mixed inks for direct application. Also, this mechanism is very much dependent on PMS codes. This color system is quite useful for crucial design elements. For color consistency, we recommend this approach. Conversely, employing a hybrid system is best for retail cereal packaging. Thus, you can achieve the required photographic detail and consistency.

Finishing Techniques to Increase Shelf Appeal & Tactile Quality

-

There are plenty of add-ons, but we will limit our explanation to a few only. For instance, UV coating offers a gloss finish that is durable as well. Therefore, the box content remains safe from moisture.

-

Two very reputable laminations are often the faves of numerous food brands. Matte is non-reflective and makes the box surface feel very soft. Gloss lamination is all about shine. It can even make hues look richer.

-

For tactile effects, there are debossing, embossing and foil stamping. They offer a certain texture to your preferred areas as well as a metallic shine.

Boxit Packages is a reliable packaging company in the USA, facilitating businesses with essential add-ons, high-resolution printing, and precise coloring. Moreover, the brands flexible approach allows both small and large-scale businesses to order because it provides custom cereal boxes with no minimum order quantity. There are numerous other notable suppliers. We recommend you investigate thoroughly before choosing one.

Conclusion

Our guide today uncovered two effective printing techniques for customized cereal boxes. Both digital and offset printing are advantageous in various ways. More includes the color systems, vital to comprehend before applying high-quality images or branding elements. Lastly, we discussed cereal packaging add-ons.