A Complete Guide to Choosing the Right Baling Press Machine for Your Business

Discover the benefits of a baling press machine for efficient waste management. Reduce volume, save costs, and boost recycling efficiency for your business.

In todays fast-growing industrial and recycling sectors, efficient waste management has become a crucial priority. Companies across manufacturing, retail, agriculture, and recycling industries are constantly searching for solutions that help reduce waste volumes and optimize storage. One of the most effective tools for this purpose is the baling press machine. This powerful equipment compresses waste materials into compact bales, making storage, handling, and transportation significantly easier.

A baling press machine is widely used for compressing materials such as cardboard, plastic, paper, metal scrap, textiles, and agricultural waste. Its ability to reduce waste size by up to 90% makes it an essential investment for businesses aiming to cut operational costs and improve sustainability. With increasing environmental regulations and a global push toward waste reduction, having a baling press machine is no longer optional it is a competitive advantage.

Why Businesses Need a Baling Press Machine

The primary benefit of a baling press machine is its ability to streamline waste management. Instead of letting waste pile up and occupy valuable space, businesses can convert loose materials into compact, stackable bales. This helps maintain a cleaner and safer workspace while reducing disposal frequency and transportation expenses.

Another major advantage is the potential for revenue generation. Many recycling companies and scrap dealers offer competitive prices for well-compressed bales. By using a baling press machine, businesses can turn their waste into a profitable resource.

Additionally, automating waste handling reduces manual labor requirements. Workers spend less time managing bulky waste, improving overall productivity and efficiency.

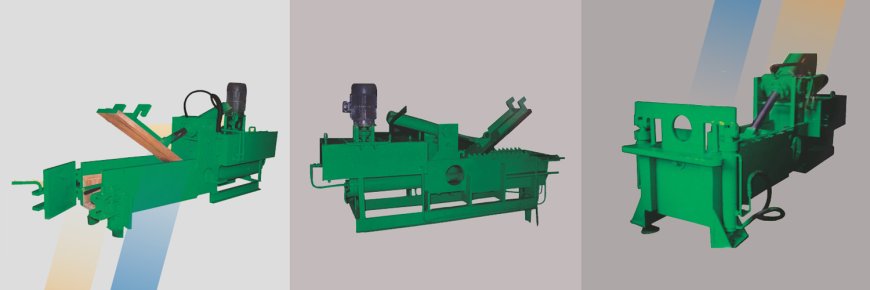

Types of Baling Press Machines

There are several types of baling press machines, each designed for specific materials and production volumes:

1. Vertical Baling Press Machine

Ideal for small to medium businesses, retail stores, warehouses, and industries generating moderate waste. It is affordable, easy to operate, and takes up minimal floor space.

2. Horizontal Baling Press Machine

Best suited for large-scale operations requiring high output. It can handle continuous waste streams and produce heavier, more uniform bales.

3. Fully Automatic Baling Press Machine

Designed for high-speed industries such as paper mills, recycling plants, and production factories. It offers maximum automation, minimal labor, and consistent bale quality.

Choosing the right type depends on waste volume, material type, available space, and budget.

How to Choose the Best Baling Press Machine

When selecting a baling press machine, consider these factors:

-

Material Compatibility: Ensure the machine supports the waste materials you handle regularly.

-

Bale Size & Weight: Choose a machine that produces bale sizes suitable for storage and buyers requirements.

-

Automation Level: Assess whether you need manual, semi-automatic, or fully automatic operation.

-

Safety Features: Look for emergency stop switches, safety interlocks, and user-friendly controls.

-

Maintenance & Durability: Opt for machines made from high-quality steel with easy-to-maintain components.

Conclusion

A baling press machine is an invaluable asset for any business looking to enhance waste management, save costs, and promote environmental sustainability. By selecting the right machine, companies can achieve better efficiency, reduce clutter, and even generate additional revenue from recyclable waste.

If your business is ready to upgrade its waste-handling processes, investing in a baling press machine is a smart and future-ready decision.