Laser Cutting Fabrication Pune: Precision, Performance, and Perfection

where precision and performance are crucial, laser cutting fabrication serves as a vital tool in the manufacturing ecosystem. Combined with the broader sheet metal fabrication process, it offers unparalleled accuracy, versatility, and cost-efficiency across a wide spectrum of industries.

In the heart of Maharashtras industrial growth lies Pune a hub for innovation, engineering, and manufacturing excellence. Among its many manufacturing services, laser cutting fabrication in Pune stands out as a game-changer, offering unmatched precision, speed, and versatility in metalworking. With industries evolving rapidly, businesses increasingly turn to advanced fabrication processes to meet stringent quality and performance standards. At the core of this transformation is the sheet metal fabrication process, a critical backbone for numerous applications across sectors like automotive, aerospace, construction, and electronics.

What Is Laser Cutting Fabrication?

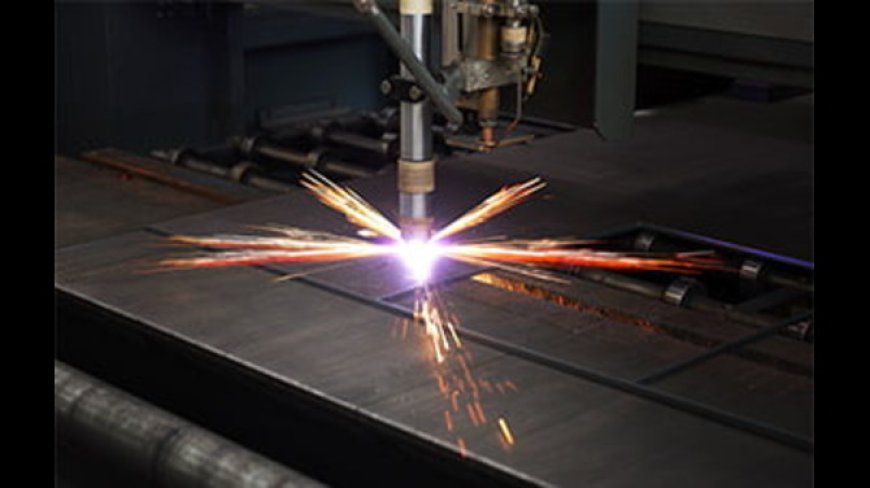

Laser cutting fabrication pune is a modern manufacturing technique where a high-powered laser beam is used to cut, engrave, or etch materials, primarily metals, with remarkable accuracy. Unlike traditional cutting methods, laser cutting ensures minimal material wastage, tight tolerances, and superior edge quality making it an indispensable part of the sheet metal fabrication process.

In Pune, the demand for laser cutting fabrication is fueled by the city's strong base of automotive OEMs, precision engineering firms, and infrastructure projects. From small-scale units to large-scale manufacturing plants, laser cutting provides a competitive edge through efficient turnaround times and consistent quality.

Key Advantages of Laser Cutting Fabrication in Pune

- Unmatched Precision

Laser cutting offers high-precision results, capable of creating intricate geometries and detailed patterns that manual or mechanical cutting tools cannot achieve. This level of precision is essential in high-tolerance industries like aerospace and electronics. - Material Versatility

Whether its mild steel, stainless steel, aluminum, brass, or even non-metals like plastics or composites laser cutting works efficiently on a wide range of materials. This adaptability enhances the overall sheet metal fabrication process. - Cost-Effective for Short and Long Runs

With reduced setup time and no need for hard tooling, laser cutting fabrication in Pune is ideal for both small batch prototypes and mass production runs, offering cost-effectiveness at every scale. - Clean Cuts with Minimal Finishing

The laser beam produces clean, burr-free edges that often require little to no post-processing. This reduces production time and helps maintain the integrity of the material. - Faster Turnaround Times

Automation and CNC integration in laser cutting machines enable faster operations. For manufacturers in Pune racing against tight project deadlines, this speed is a significant advantage.

The Sheet Metal Fabrication Process Explained

The sheet metal fabrication process is a series of manufacturing steps used to shape and assemble flat metal sheets into desired structures or products. It combines various techniques, including cutting, bending, welding, and assembling. In Punes advanced industrial setting, the integration of laser cutting within this process brings a significant leap in performance and accuracy.

Major Steps in the Sheet Metal Fabrication Process:

- Design & Prototyping

The process starts with CAD design, where engineers create a digital prototype of the product. Laser cutting machines read these designs for precision cutting. - Laser Cutting

This is the first stage of actual fabrication. As one of the most vital stages, laser cutting fabrication in Pune involves slicing the metal sheets according to the design layout. Accuracy and speed at this stage lay the foundation for the entire fabrication process. - Bending & Forming

After cutting, the metal sheets are bent using press brakes. This process transforms flat metal pieces into three-dimensional structures. - Welding & Joining

The formed parts are then welded together using MIG, TIG, or spot welding. Pune-based fabricators often employ robotic welding systems for consistent quality. - Finishing & Assembly

This includes polishing, powder coating, painting, and final assembly, depending on the products requirements. - Quality Control

Throughout each stage, rigorous quality checks ensure compliance with design specifications, tolerances, and industry standards.

Applications Across Industries

Laser cutting fabrication in Pune is not limited to a single industry. Its precision and reliability make it suitable for a wide variety of applications:

- Automotive: Engine brackets, body panels, and exhaust components

- Construction: Facade panels, staircases, railings, HVAC systems

- Aerospace: Precision aircraft components, enclosures

- Electronics: Enclosures, racks, cable trays

- Furniture: Custom metal furniture frames and decorative elements

- Agriculture: Implements, enclosures, and structural frames

The flexibility of laser cutting allows designers and engineers in Pune to innovate and develop custom solutions tailored to each sectors unique demands.

Why Choose Samarth Sharp Edge?

If youre looking for reliable and high-precision laser cutting fabrication in Pune, Samarth Sharp Edge offers industry-leading services backed by experience, modern infrastructure, and a skilled workforce.

Heres what makes them a trusted name in Punes sheet metal industry:

- Advanced Machinery: Equipped with high-powered CNC laser cutting machines that deliver precision cuts with fast turnaround times.

- Custom Fabrication: From prototypes to full-scale production, Samarth Sharp Edge handles diverse requirements across industries.

- Quality Assurance: Stringent quality control systems ensure every product meets the highest standards.

- Timely Delivery: With a well-coordinated team and optimized processes, they ensure on-time project completion every time.

- Competitive Pricing: High-quality fabrication at cost-effective rates helps clients stay within budget without compromising on quality.

The Future of Fabrication: Embracing Laser Technology

The demand for laser cutting fabrication in Pune is poised to grow with the rise of smart manufacturing and Industry 4.0. Automation, IoT integration, and real-time data analysis are transforming how metal fabrication is performed, making it smarter and more efficient. Laser cutting aligns perfectly with these innovations due to its compatibility with digital control systems and minimal manual intervention.

As businesses focus on sustainability and waste reduction, laser cutting also contributes to eco-friendly practices by optimizing material usage and reducing energy consumption compared to older methods.

Conclusion

In a dynamic city like Pune, where precision and performance are crucial, laser cutting fabrication serves as a vital tool in the manufacturing ecosystem. Combined with the broader sheet metal fabrication process, it offers unparalleled accuracy, versatility, and cost-efficiency across a wide spectrum of industries.

For companies seeking advanced metalworking solutions, embracing laser cutting is no longer optional it's essential. Whether you're prototyping a new product or scaling up production, choosing a reliable partner like Samarth Sharp Edge ensures that your fabrication needs are met with precision, professionalism, and performance-driven excellence.